Global Semiconductor Manufacturer Manages Disruption and Adapts to Strategy Changes

A change in deeply rooted perspectives

Disruption is occurring across all industries, driven in part by new competitive models, technological advances and changing customer preferences. Leaders pivot business strategies with increasing frequency, either to get an edge on the competition or fend off its equivalent in an “Amazon Effect.” Mergers and acquisitions have reached an all-time high as companies pursue step changes in innovation, access to new markets and economies of scale.

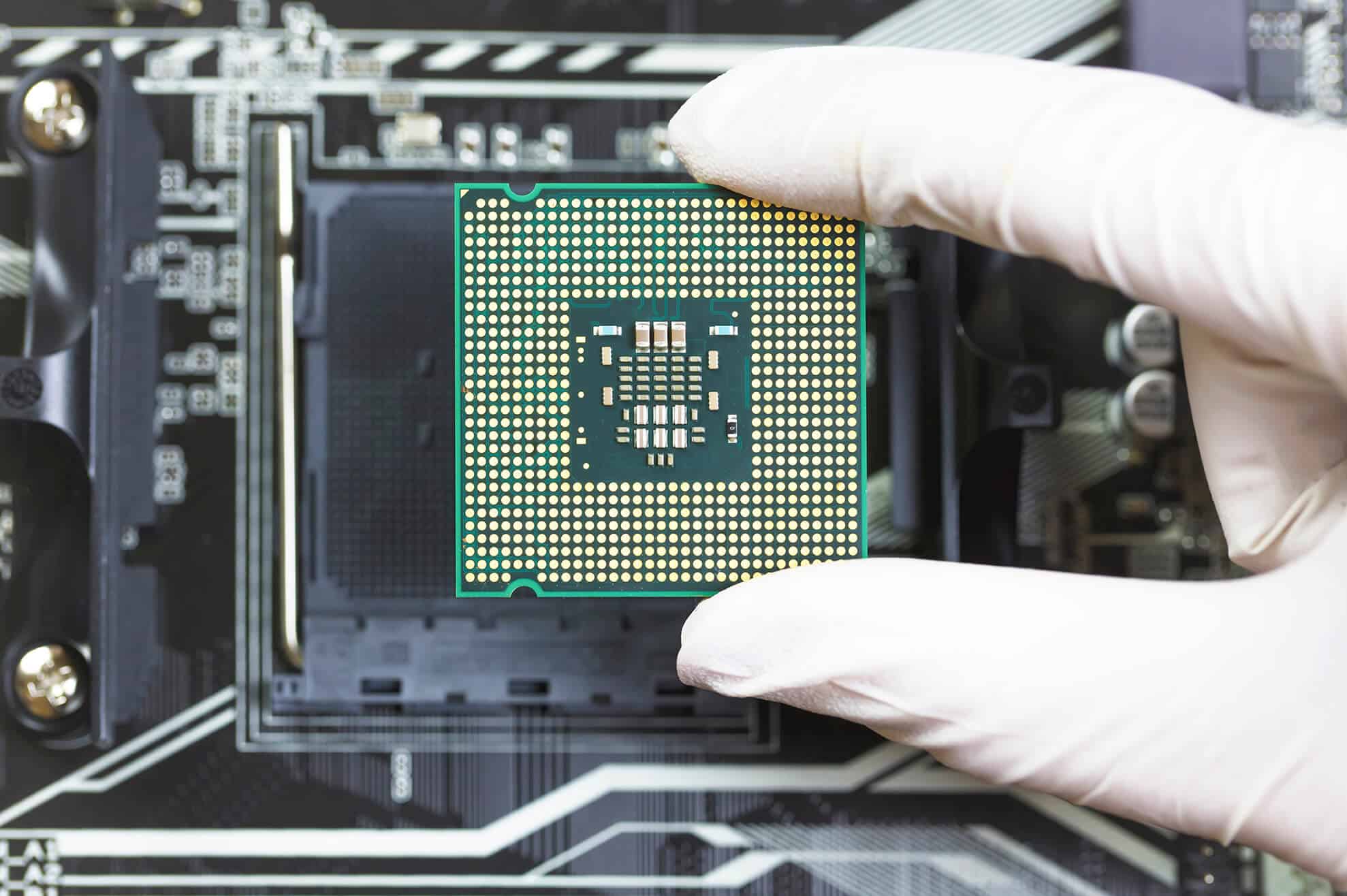

With each acquisition comes the opportunity to reset deeply rooted perspectives and make minor or even wholesale shifts in corporate strategy — potentially reinventing the entire business. This was the case with a global semiconductor manufacturer’s transformation into a predominately fabless manufacturing model. The manufacturing firm has revenues of over $5 billion with a complex network of more than 30 factories and 40 distribution warehouses. Yet seven years ago when the first of three transformative stages began, 90% of the company’s manufacturing was done in-house.

Challenges

- The struggle to maintain manufacturing visibility while shifting from an in-house to a fabless strategy

- Inaccurate and slow inventory reporting and the resulting risk of regulatory non-compliance, all caused by siloed systems

- Increased scrap and missed customer commitments due to difficulties identifying yield issues early in the manufacturing cycle

- Overpayments for external services resulting from complex, manual and error-prone contract reconciliation processes

Results

- Successfully achieved the same level of quality and yield conformance for both internal and external manufacturing across each stage of the transformation

- Increased inventory accuracy from 85% to 99.9% and achieved 100% inventory accountability for Sarbanes- Oxley compliance

- Reduced supplier errors by 95%, lowering scrap and rework costs while increasing product availability

- Eliminated supplier overcharges and raised productivity by automating contract compliance

New compliance, financial and service needs

When a lack of visibility and consistent quality across the company’s internal manufacturing operations reached critical mass, significant business concerns had to be addressed:

Insufficient accuracy and timeliness of global inventory reporting had raised the risk of non-compliance with the Sarbanes-Oxley Act of 2002 (SOX). The disconnect between siloed operational and financial systems required an extensive exchange of spreadsheets. The resulting time-consuming, error-prone reconciliation processes meant that reporting was slow, cumbersome and inaccurate.

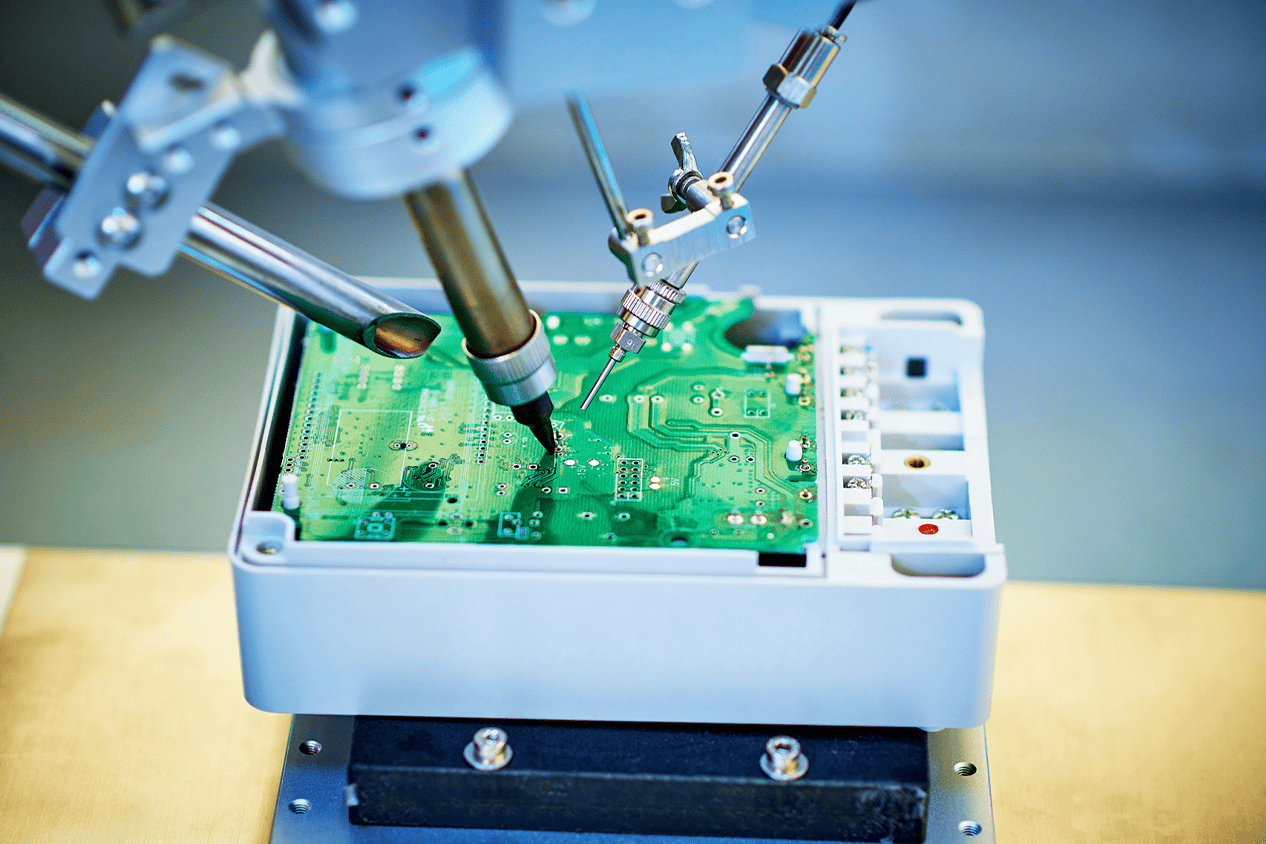

Quality control issues across disparate systems were putting profits in jeopardy. The absence of full visibility into manufacturing steps across disparate internal systems made it difficult to identify yield issues early in a cycle and take corrective action in a timely manner. This resulted in costly write-offs and product shortages that impacted customer commitments.

The company selected e2open’s Manufacturing Collaboration application to gain deep visibility into manufacturing and quality systems. Once connected to the firm’s underlying systems, the e2open platform collected, cleansed and harmonized manufacturing, quality and inventory data. This data created a single source of truth for all business decisions and provided a holistic view of inventory across the entire operation. Automatic updates and closed-loop integration between systems ensured that all decision- making was based on the latest information.

Operations and finance could now access the same data, leveraging a single source of truth to drive faster, better and more confident business decisions.

The outcome was a big step forward that enabled faster, better and more confident business decisions. With e2open Manufacturing Collaboration in place, finance gained timely and accurate reporting of inventory for its compliance requirements. Finance also benefited from an increase in productivity by automating the labor-intensive and error-prone exchange of spreadsheets and manual reconciliation processes. Operations gained visibility into product quality and yield issues early in the manufacturing process so steps could be taken proactively to reduce scrap and ensure product availability.

Partial change in strategy due to an acquisition

Just a year later, the company acquired a leading graphics chip provider to expand market share in a strategic and fast-growing segment. The acquisition required a new manufacturing strategy because the graphics chip provider was fabless, with 100% of its manufacturing outsourced to third parties.

Integrating a company with a fabless business model presented a new challenge: establishing the same visibility and control of external systems as internal systems. Consistent reporting compliance and quality conformance were now required across internal and outsourced operations. Taking a step back to spreadsheet exchanges was not an option.

Fortunately, the same e2open platform architecture deployed to provide internal visibility was also designed to connect to both in-house and external systems. To integrate the operations, manufacturing and quality systems at contract manufacturers’ locations were connected via e2open’s business network, e2net. Data could then be automatically extracted and normalized before it was added to a unified data model. This extended the holistic view to the entire business, regardless of whether manufacturing was performed within or outside its four walls.

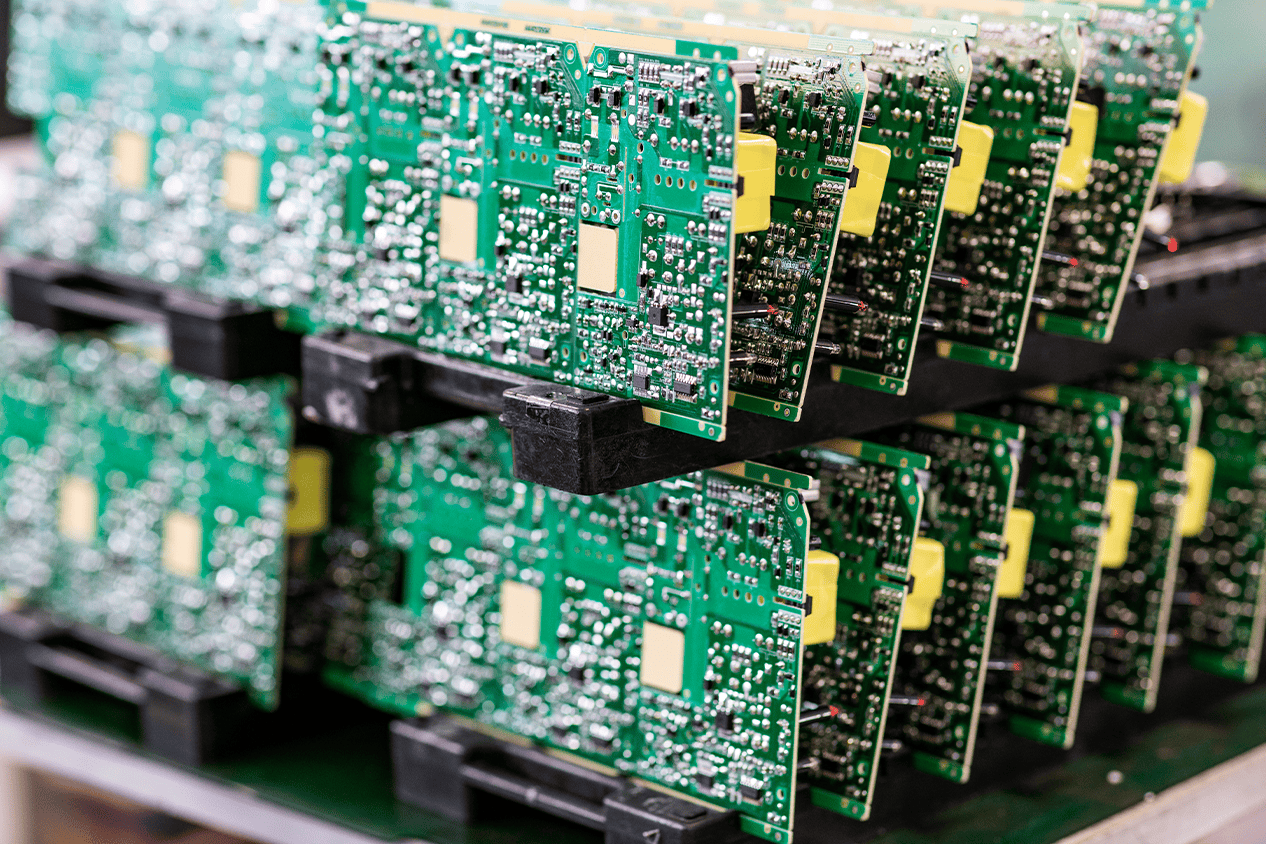

Strategic transformation to a fabless business

Along the way, the company decided to transform its traditional business by shifting from what was previously 90% in-house manufacturing to 80% outsourced. This transition to a fabless strategy would allow all operations to take advantage of the latest manufacturing technologies, make the company more agile and responsive and significantly reduce the capital intensity of the business.

As production shifted to external suppliers, connections were established through the e2net business network to underlying manufacturing and quality systems.

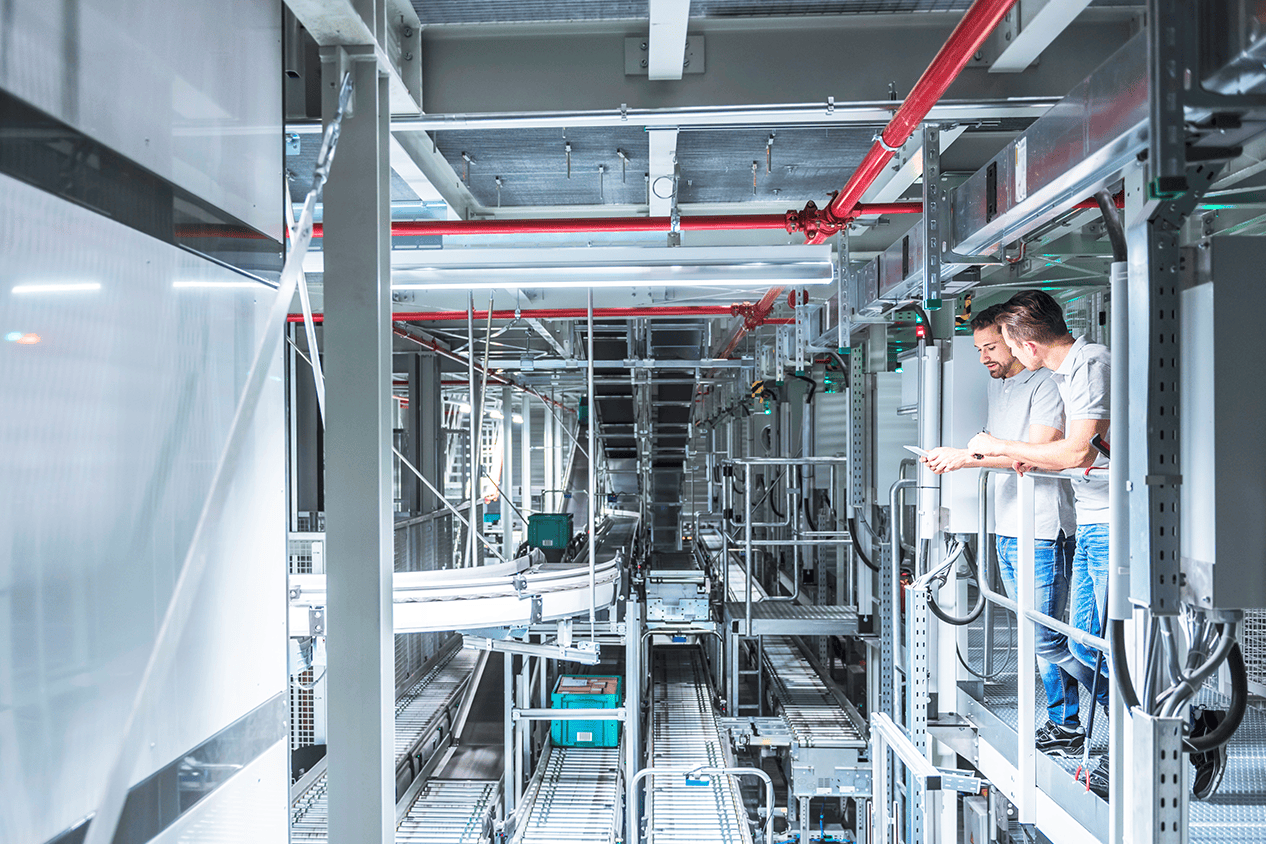

From a supply chain management and financial reporting perspective, e2open’s platform made the transition straightforward. As production shifted to external suppliers, connections were established through the e2net business network to underlying manufacturing and quality systems. Today, e2open’s platform processes more than 150,000 transactions a day for the semiconductor manufacturer and supports more than 500 internal and external users.

In addition to visibility, the shift to outsourced manufacturing brought another challenge: addressing overpayments for services rendered. Often discrepancies exist between the actual services provided and the services that are invoiced and between agreed contractual prices and what is invoiced. E2open’s Manufacturing Collaboration application automates the reconciliation of services with invoices and helps ensure accurate, timely payments. The application also improved productivity by streamlining the labor-intensive reconciliation of purchase orders, invoices and contracted price schedules.

Dramatic results on the road to a fabless model

The manufacturer’s journey unfolded in three stages over a seven-year period, starting with the pressing need for improved visibility to comply with SOX regulations and respond to financial performance and customer service pressures. Once in place, the visibility platform was instrumental to integrating the newly acquired fabless chip provider. This in turn created a pathway to transform the entire business to execute successfully on a more competitive fabless strategy. The seamless transition to fabless manufacturing brought about significant benefits for the firm:

Inventory accuracy and compliance

across global operations, with accuracy increasing from 85% to 99.9% and inventory accountability reaching 100% for SOX compliance

Agility and scalability

including the ability to accommodate capacity variations and shifts, and expand contract supplier bases as business requirements evolved

Margin and customer service lifts

Margin and customer service lifts, reducing supplier error and scrap by 95% and improving product availability by gaining deep visibility into yield issues early in the manufacturing cycle

Enhanced productivity

higher-value tasks

Dramatic cut in supplier disputes and overcharges

achieved by automating the three-way matching of actual services provided with invoices and contractual pricing

IT complexity reduction

that included cutting the number of IT systems by a factor of 4, thus reducing the total cost of ownership

Solution

Increased

inventory accuracy from 85% to 99.9%

Reduced

supplier errors by 95%

Eliminated

supplier overcharges and raised productivity

Increased

reporting speed to close month-end books within two hours

Subscribe to receive e2open updates

Interested in learning more? Stay current with the latest e2open news – from company updates to thought-leadership pieces, and so much more!

Complete this form to subscribe to e2open updates.

Let's get started.