The planning engine behind global industry leaders

TOO MANY UNCERTAINTIES

Supply chain planning has changed. Most companies haven’t kept up.

Traditional planning solutions are ill-equipped to deal with the hazy uncertainties of modern supply chains. Check out the biggest headaches facing planners today.

Solution Brief

Shadow Planning: Reveal the blind spots in your supply chain

Learn how a supply chain digital twin can help you anticipate disruptions before they affect your bottom line.

A REVOLUTIONARY APPROACH

Connected Planning is built for the messy reality of supply chains

With AI-powered decisioning and automation, Connected Planning from e2open lets you break through silos and respond instantly to both risks and opportunities.

CONNECTED VISIBILITY

Combine downstream channel data with upstream supply visibility

Use Case: Your contract manufacturer (CM) is encountering unforeseen delays. By incorporating n-tier supplier data, Connected Planning lets you identify the causes of part shortages at your CM’s supplier and collaborate with them to find mutually-beneficial solutions and maintain production schedules.

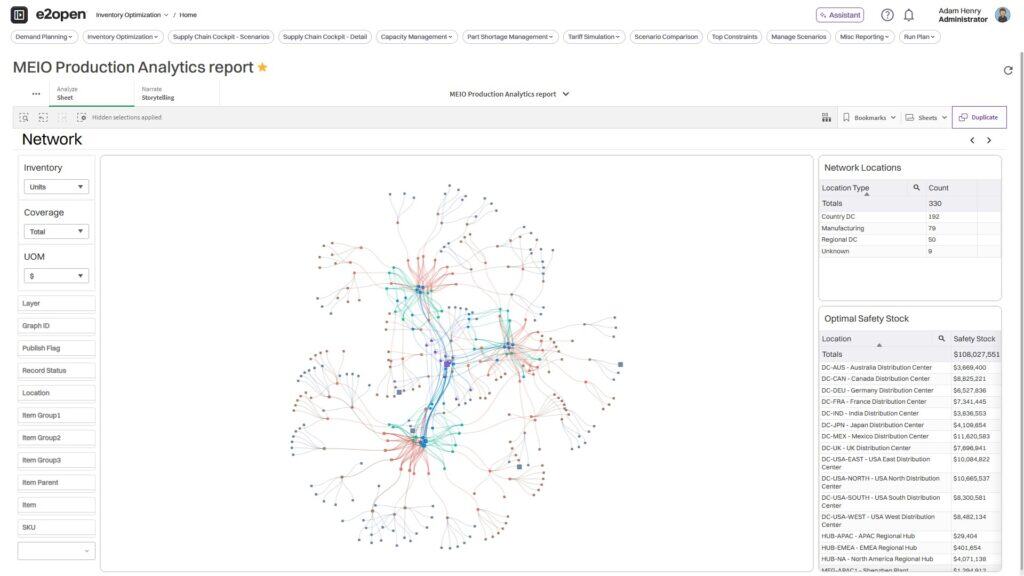

CONNECTED MODEL

Teams work from one source of truth for faster collaboration

Use Case: A global electronics manufacturer faces sudden demand spikes for a new product across multiple regions. With Connected Planning, planners in North America, Europe, and Asia collaborate in real time, sharing insights and updating scenarios as market conditions change. The team quickly identifies bottlenecks, reallocates inventory, and adjusts production schedules, ensuring products reach customers faster and maintain service level expectations.

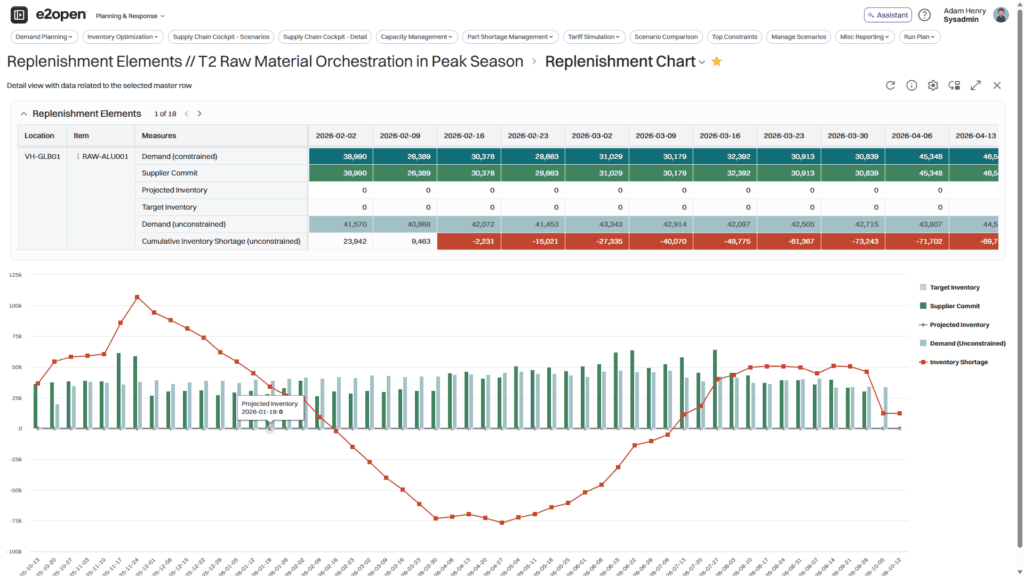

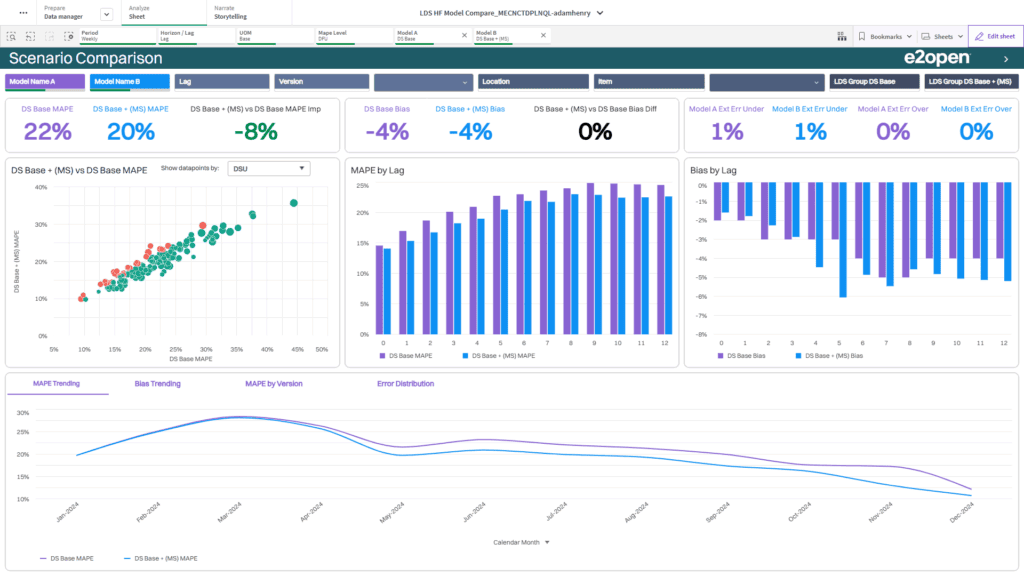

CONNECTED SCENARIOS

Model, compare, and promote “what-if” scenarios in real time

Use Case: When your competitor faces disruption, e2open’s scenario planning capabilities enable your team to quickly model inventory changes, expedite orders, evaluate impacts, coordinate responses, and update baseline plans to capture opportunities and reduce risks. Connected planning lets planners collaborate seamlessly, test ideas, and quickly respond to disruptions or opportunities, all within a single connected platform.

CONNECTED WORKFLOWS

Bring people and application systems together in one workflow

Use Case: A food manufacturer builds a workflow to automate S&OP planning across plants and distribution centers. As planners align demand forecasts with constrained supply, the Connected Planning system orchestrates each step, assigning tasks, tracking progress, and monitoring compliance, so every update and adjustment is instantly visible, auditable, and executed according to company standards.

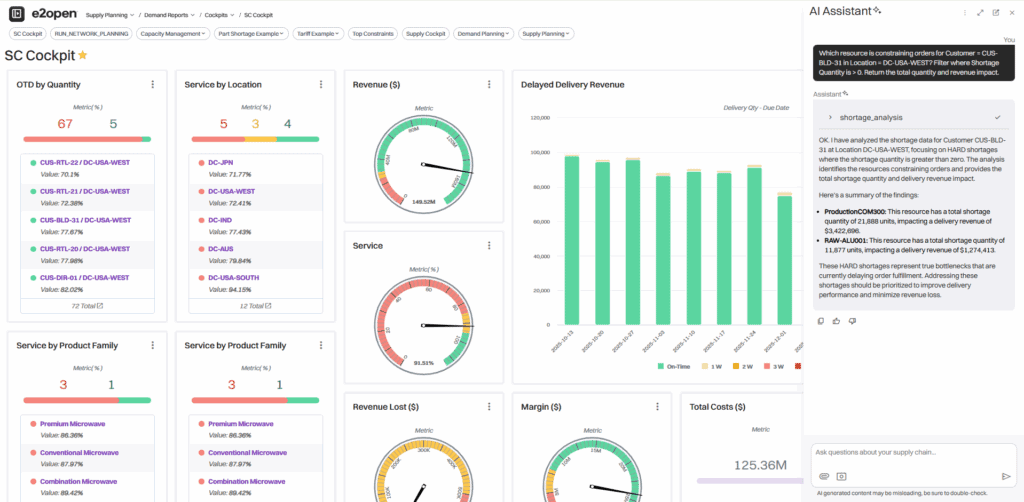

CONNECTED DECISIONS

Give planners the power of AI and automation to align decisions with goals

Use Case: If a shipment of raw materials is delayed for 5 days due to port congestion, weather, or terrorist attacks on vessels, you can link the transportation disruption back to the plan for an immediate impact assessment and initiate corrective action if needed. Connected Planning gives planners the power of AI and the flexibility to work at any level of detail or time horizon by automating micro-decisions, aligning every decision with business goals for greater agility, resilience, and profitability.

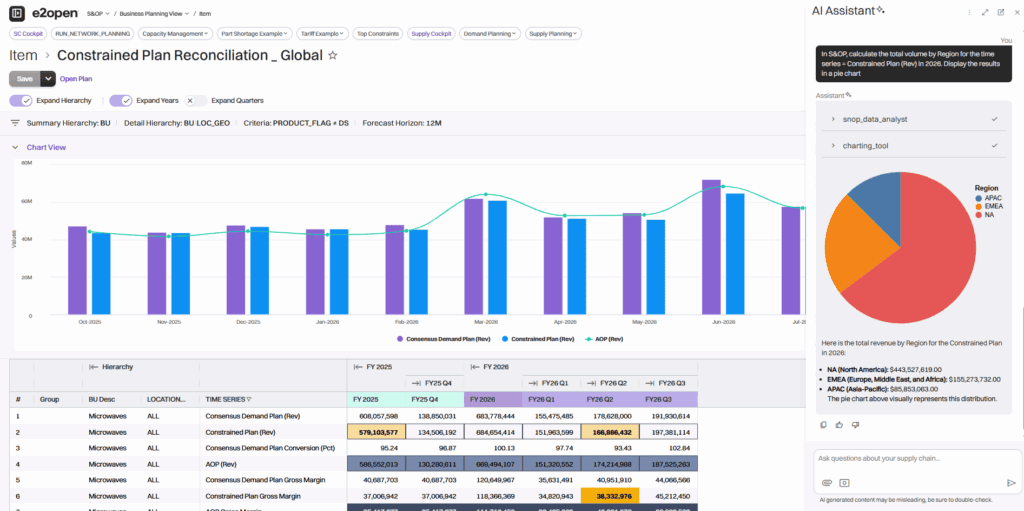

CONNECTED INTELLIGENCE

Upskill planners even if they lack certain experience or skills

Use Case: Consider a new planner dealing with an unexpected disruption in the supply plan from a climate event and isn’t quite sure what to do. Simply engage the agentic digital assistant to instantly learn the root cause is an impacted supplier, gain expert analysis of orders at risk, identify alternative suppliers, compare total landed costs considering tariffs and logistics, screen suppliers for regulatory compliance, and receive detailed step-by-step guidance on how to update purchase orders. Expert answers and actionable insights, fast.

CASE STUDY

New product introductions require a connected planning solution

It’s tough to make accurate forecasts and ensure inventory alignment, but new product introductions (NPIs) add extra layers of complexity. Discover how e2open helped one company refine its NPI forecasting models by analyzing patterns from multiple data points.

Mastering the Complexity of Make-to-Order Supply Chains

Make-to-Order (MTO) businesses are some of the most complex, and most fascinating, supply chains to work with. Every customer order is a new project—often with customized specifications, tight timelines, and dependencies that span multiple suppliers and production facilities. Unlike Make-to-Stock (MTS) operations, where products are built in anticipation of demand, MTO businesses commit to customers before they design the solution, procure components, and begin production. […]

Nucleus Research: Assessing the Value of e2open Supply Chain Planning for Manufacturers

Common supply chain manufacturing challenges Does your manufacturing organization struggle with fragile supply chains, poor supplier visibility, and inefficient planning processes? You’re not alone. Key benefits of e2open supply chain planning for manufacturers Manufacturing organizations face unprecedented challenges in today’s market: raw material scarcity, inaccurate demand forecasting, and increasingly complex global supply chains. The Nucleus Research report examines how e2open’s integrated platform addresses these pain points with dramatic results: 5-35% reduction in operational costs through inventory optimization and streamlined processes 17% improvement in service level performance with enhanced visibility and real-time tracking 15% increase in employee productivity by automating manual workflows

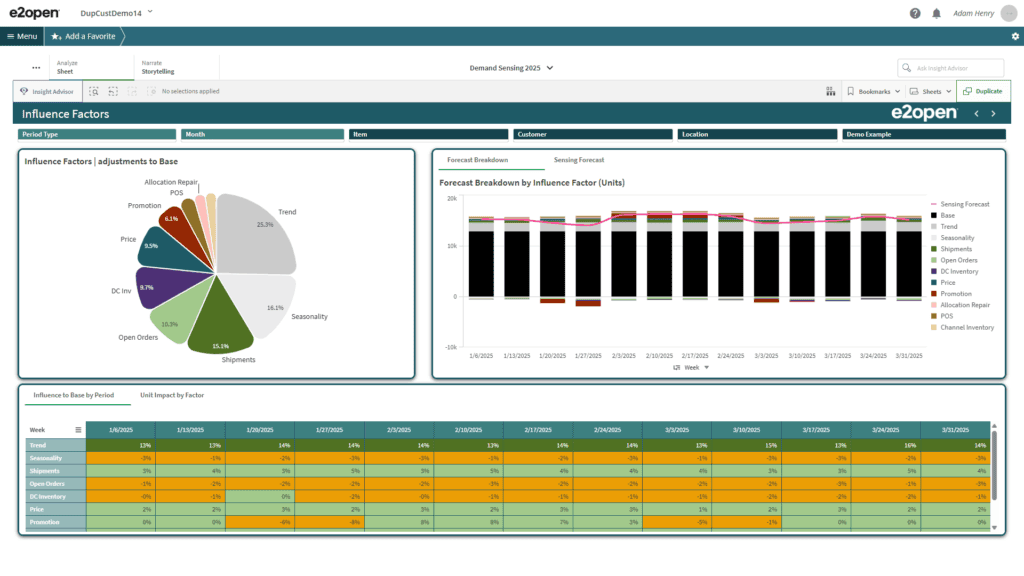

Candymaker Leverages Demand Sensing AI to Resolve Volatile Demand

Demand intelligence keeps sweets on the shelf This iconic candy and snacking brand struggled with cumbersome manual processes and zero visibility into changing demand patterns, leading to missed opportunities for taking timely, corrective measures. Thanks to Demand Sensing Artificial Intelligence (AI) solutions from e2open, they can now identify causal demand signals, automatically generate highly accurate daily forecasts, and preemptively adjust supply to keep their products on the shelf while reducing stockouts. Read the full story here and connect with e2open to discuss how our demand intelligence solutions can help your company optimize supply chain agility.

Break the Planning Silo to Gain Agility

Today’s complex, intertwined supply chains face a volley of volatility, uncertainty, and disruptions that extend well beyond their four walls. It is all too clear following the pandemic that risks anywhere in the layers of multi-tier suppliers and partners can and will impact a company’s bottom line. The pressure for companies to generate more value and better performance from their supply chains hasn’t changed. When it comes to organizational strategy and the expectations for financial performance, customer satisfaction, and contribution to environmental, social, and corporate governance (ESG) goals — that pressure is only increasing. More than ever, companies are focused on maximizing the returns from their existing investments and amplifying benefits across the enterprise.