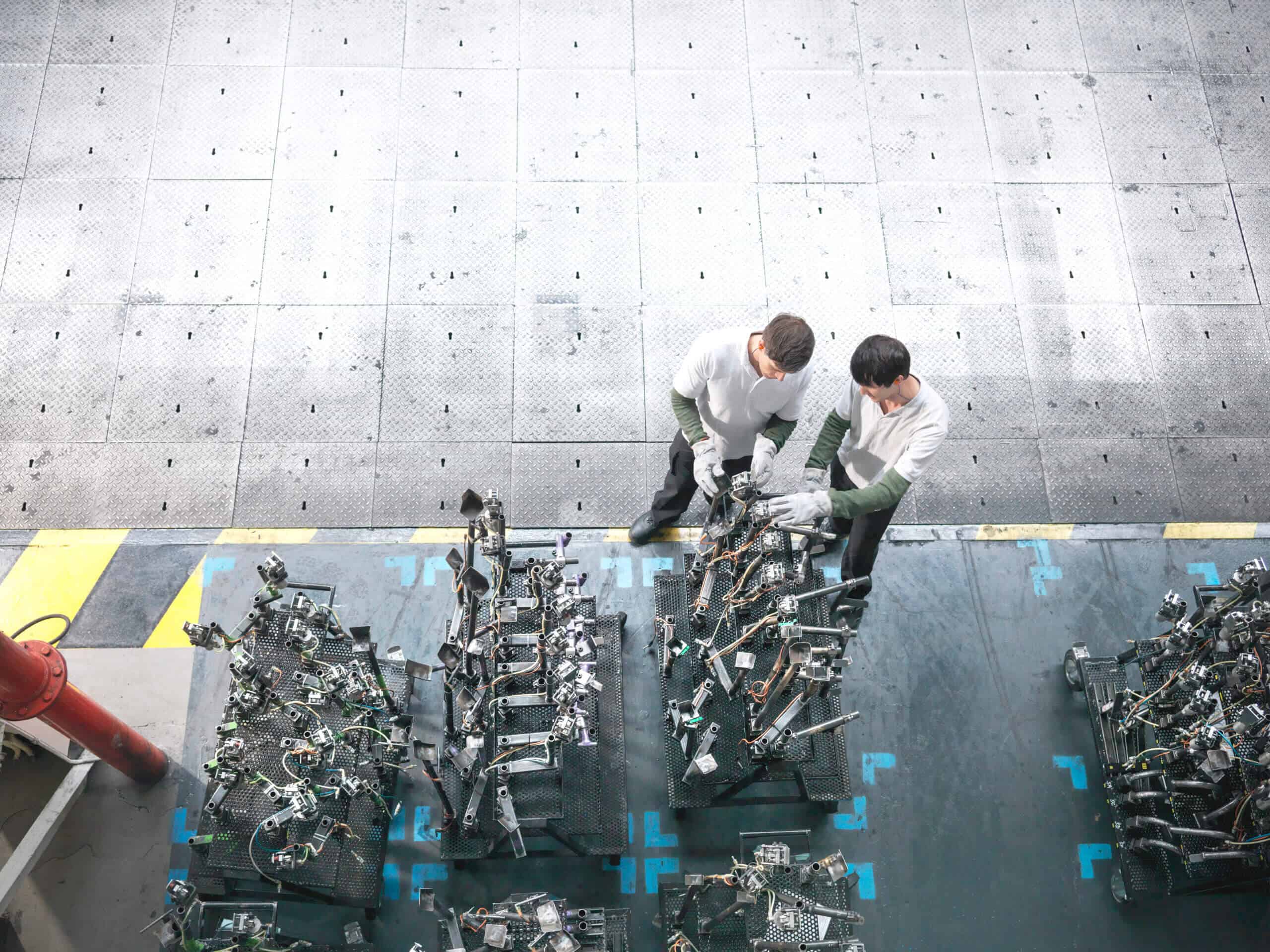

Gain Insight into All Production Stages with Manufacturing Collaboration

Gain greater levels of visibility and control despite expanding business complexities and shrinking timelines. E2open Manufacturing Collaboration provides complete visibility into end-to-end manufacturing processes and costs at all stages of production to improve operational efficiency, collaborate on product design, and reduce invoicing inaccuracies. As blind spots disappear, profitability increases.

True end-to-end visibility and collaboration for global manufacturing processes

Financial benefits of outsourcing diminish due to poor visibility and collaboration

Sourcing globally and leveraging contract manufacturers can lower manufacturing costs but simultaneously have the opposite effect. Manufacturing complexities, mergers and acquisitions, communication disconnects, inaccurate service-based invoices, and quality and inventory management issues are just some of the challenges that can negate financial benefits. Without the ability to collaborate across tiers, expand, integrate systems and partners, and launch new products while meeting quality, compliance, and traceability requirements, profitability is watered down. Even the best efforts fail to realize a company’s vision.

Visibility and collaboration drive profitability

Gain deep insight into internal and external factory production. Collaboration and automation across your end-to-end manufacturing ecosystem give you the visibility and control to improve manufacturing and performance while reducing costs.

Improve operational efficiency

Automatically monitoring key metrics and course-correcting quality, supply, service, and inventory processes helps increase yields, improve customer service, and lower financial liability from excess inventory.

Identify issues proactively

Pinpointing problems early in production helps you reduce scrap, shorten delays, and address issues stemming from high inventory costs, poor quality, and inefficient production.

Introduce new products faster

The accurate transfer, tracking, and validation of manufacturing and testing instructions helps you improve quality and significantly reduce product introduction cycle times.

Eliminate overpayments

The system automatically captures all service-based costs incurred by manufacturers and logistics partners for invoice validation against contracted amounts to eliminate the payment of incorrect charges.

Extend control across all tiers

Brand owners can establish a more profitable and efficient business by extending internal control to both distributed internal production and contracted production processes.

Make informed, strategic decisions

Validated and aggregated transactional data from product lifecycle management, manufacturing execution, and quality systems helps eliminate blind spots for more informed decision-making.

30-50%

Improvement in supply issue response times

20-30%

Decrease in excess and obsolescence costs

25%

Reduction in product introduction cycle times

More applications in the supply ecosystem

Customers

Testimonials

Improve efficiency, quality, and accuracy with end-to-end visibility and collaboration.