People often yearn for their past selves, not just a time and place. Numerous events in human history have had such a profound impact that life will never be the same because of them.

The slave trade between the 16th and 19th centuries led to devastating social and economic effects on many parts of the globe. The First World War was a major global conflict that involved more than 100 countries, laying the grounds for the rise of new world orders. The introduction of electricity in the 19th and early 20th centuries made it a fundamental part of modern life, powering homes, businesses, and industries; the Spanish Flu that infected nearly a third of the world’s population and killed millions.

Fast forward to another World War, industrialization, and modernization of the commercial industry, transportation, medicine, and space travel. The launch of the World Wide Web in 1989 accelerated commerce, business, information sharing, and more.

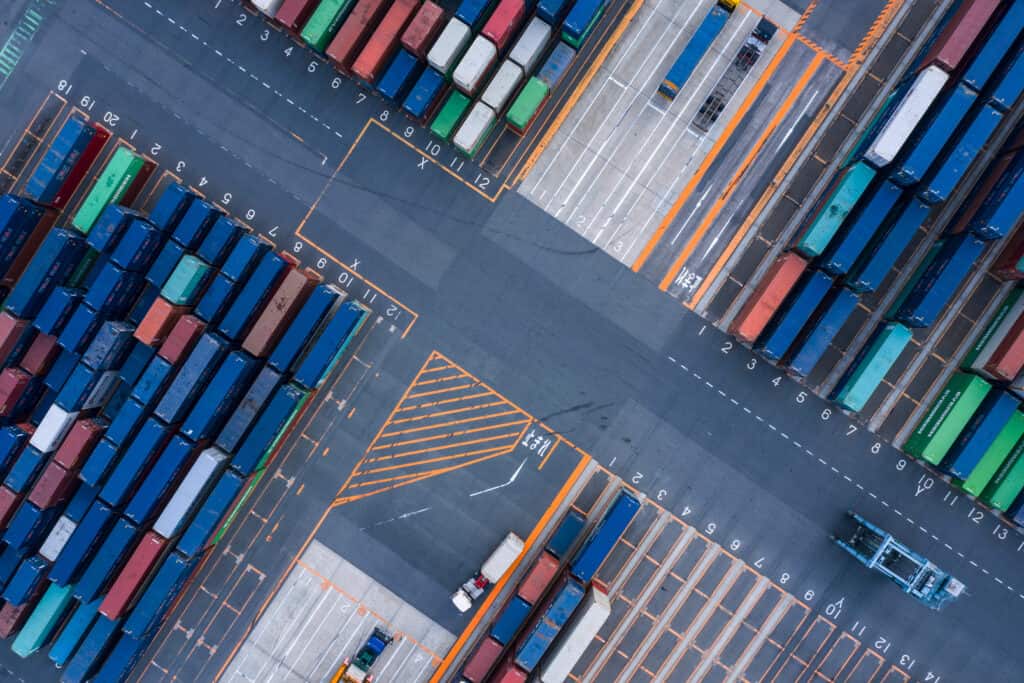

Supply chains evolved and were impacted positively and negatively by global events along the way. Digitization and transformation were leading topics in the early 2000s as most production shifted to higher-risk yet lower-cost countries over the decades. Increased cross-border regulations soon followed as countries saw the need to safeguard their exports and generate revenue from imports, priming the landscape for geopolitical disruptions.

In 2017, Brexit injected considerable uncertainty into supply chains, especially for British businesses and the UK operations of multinationals that heavily depend on imports from the European Union (EU). The departure from the EU led to increased costs, labor and skill issues, and supply shortages. Companies were prompted to rethink their supply chains, update their strategies, and build new structural agility into their organizations.

Triggered by the U.S. administration in 2019, the U.S.-China tariff war shook the foundations of global trade, slapping steep tariffs on billions of dollars’ worth of goods from the EU, Canada, Mexico, and China. All these countries responded in kind, retaliating with levies on thousands of U.S. products, undoing years of value chain growth.

The disruptor that was prolonged and fast

The Covid-19 pandemic exposed vulnerabilities in production strategies and supply chains worldwide. Companies scrambled to brace for time impacts of unknown imminent changes that would eventually become the “new normal”. Those that survived were pressured to increase domestic production, reduce dependence on risky sources, and rethink strategies of lean inventories. Companies are now focusing on building supply chain resilience. This resilience is achieved through diversification of suppliers, stockpiling essential materials, and exploring production-process improvements.

The world is witnessing a transformation in global supply chains. As companies navigate these changes to protect against potential risks, the focus is shifting toward building more resilient, flexible, and agile supply chains.

Supply chain disruptions: The new normal or just the norm?

Dynamic global crises continue to challenge companies, with the escalation of conflict in the Middle East, the war in Ukraine, geopolitical complexities related to China, unexpected natural disasters, and an uneven global economy creating a sense of permanent crisis on many fronts. Moreover, the recent Houthi attacks in the Red Sea are indicative of an increasing trend in disruptions. Beyond rerouted cargo, they may contribute to higher fuel costs, triggering a rise in transportation prices and ultimately leading to increased costs for consumers.

Even amid the pandemic in 2020, supply chain leaders, advisors, and educators were already looking ahead to recalibrate, refocus, and re-establish supply chains’ functional and organizational design when emerging from the disruptive state.

Today, resilience and agility have become the dogma across every industry and segment. Nobody is impenetrable, and disruption is anticipated. Executives need to determine how to better position their company’s operating model and supply chain strategy to proactively adjust to increase their resilience to geopolitical, weather, economic, and other disruptions.

The new normal in supply chains refers to the evolving state of supply chain management in response to significant disruptions. I prefer to call it the modern standard. Here are some critical strategies to consider for your organization’s supply chain transformation.

Multi-Sourcing Suppliers and Logistics Providers:

Many companies are reassessing their outsourcing strategies amid the evolving supply chain dynamics. Country-level political risks influence the diversification agenda, prompting businesses to consider multi-sourcing from geographically diverse suppliers as a risk mitigation strategy. Furthermore, creating business continuity and resilience plans has become crucial to counter potential impacts such as fluctuating maritime shipping rates and fees, shipment delays, or damage to cargo and vessels

Shifts in Consumer Behavior:

Changing demand patterns, panic buying, and shifts in consumer purchasing preferences have significantly impacted supply chains. Ecommerce channels, once considered optional, have become indispensable in the wake of the pandemic-induced surge in online shopping. However, challenges such as labor and staffing issues, extreme weather events, and escalating costs pressure e-fulfillment and transportation processes. These factors pose a considerable challenge to maintaining customer satisfaction.

Control Towers Become Command Centers:

Control towers are no longer a luxury but a necessity. These centralized hubs provide real-time visibility, enabling businesses to monitor, manage, and respond to changes in the supply chain effectively. However, these control towers must evolve into command centers to truly navigate the intricacies of modern supply chains. This transformation equips businesses with predictive analytics and advanced decision-making capabilities, allowing them to anticipate disruptions, optimize operations, and drive strategic growth.

Strategic Inventory Planning:

In an effort to better manage the delicate balance of supply and demand, companies are increasingly investing in strategic inventory planning. This approach allows businesses to maintain optimal inventory levels, reducing the risk of stockouts or overstock situations. By leveraging data analysis and forecasting tools, companies can predict consumer demand patterns, adjust their production schedules accordingly, and ensure they have the right products available at the right time.

What’s next for supply chains?

Remember, these changes are not just temporary responses to the pandemic but represent a fundamental shift in supply chains’ operations. The global supply chain metamorphosis is still ongoing. The lessons learned from the events of the last five years have underscored the importance of resilience, flexibility, and agility in supply chains. Moving forward, companies will continue to innovate and adapt, striving to create supply chains that are efficient and robust enough to withstand future disruptions. This transformation marks a new era in global commerce that promises to be more resilient and adaptable to the ever-changing global dynamics.

If you would like to learn more about what you can do to adapt your supply chain, feel free to reach out to one of our experts.